The Creation

We transform digital ideas into real physical products through AI and Global Manufacturing.

Difficulty materializing ideas.

We live in the era of digital AI, but the processes for creating physical products remain trapped in complex, inefficient, and expensive 20th-century designs, causing entrepreneurs and companies to lose time, money, and opportunities when trying to turn their ideas into real products.

The Design Barrier

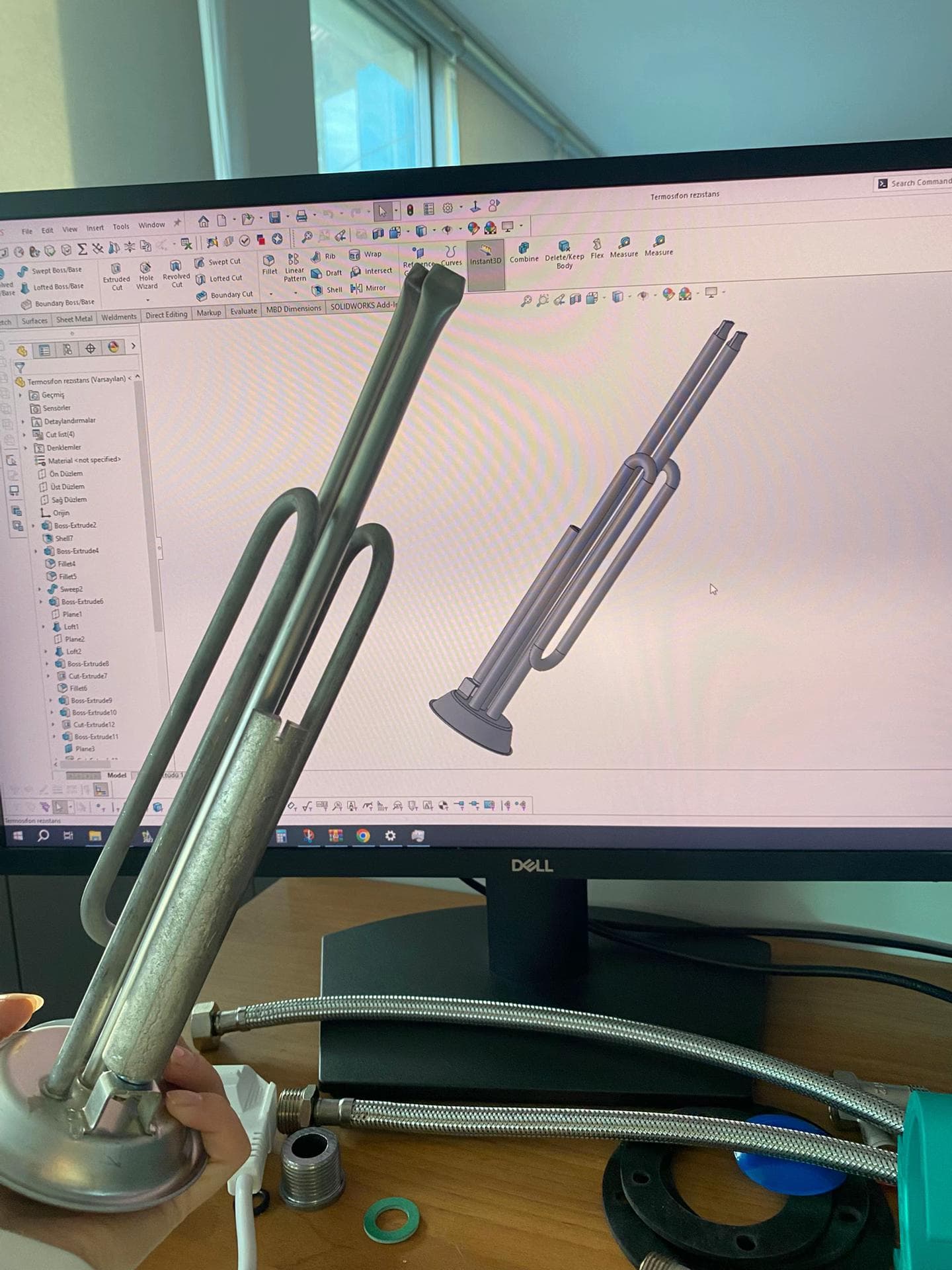

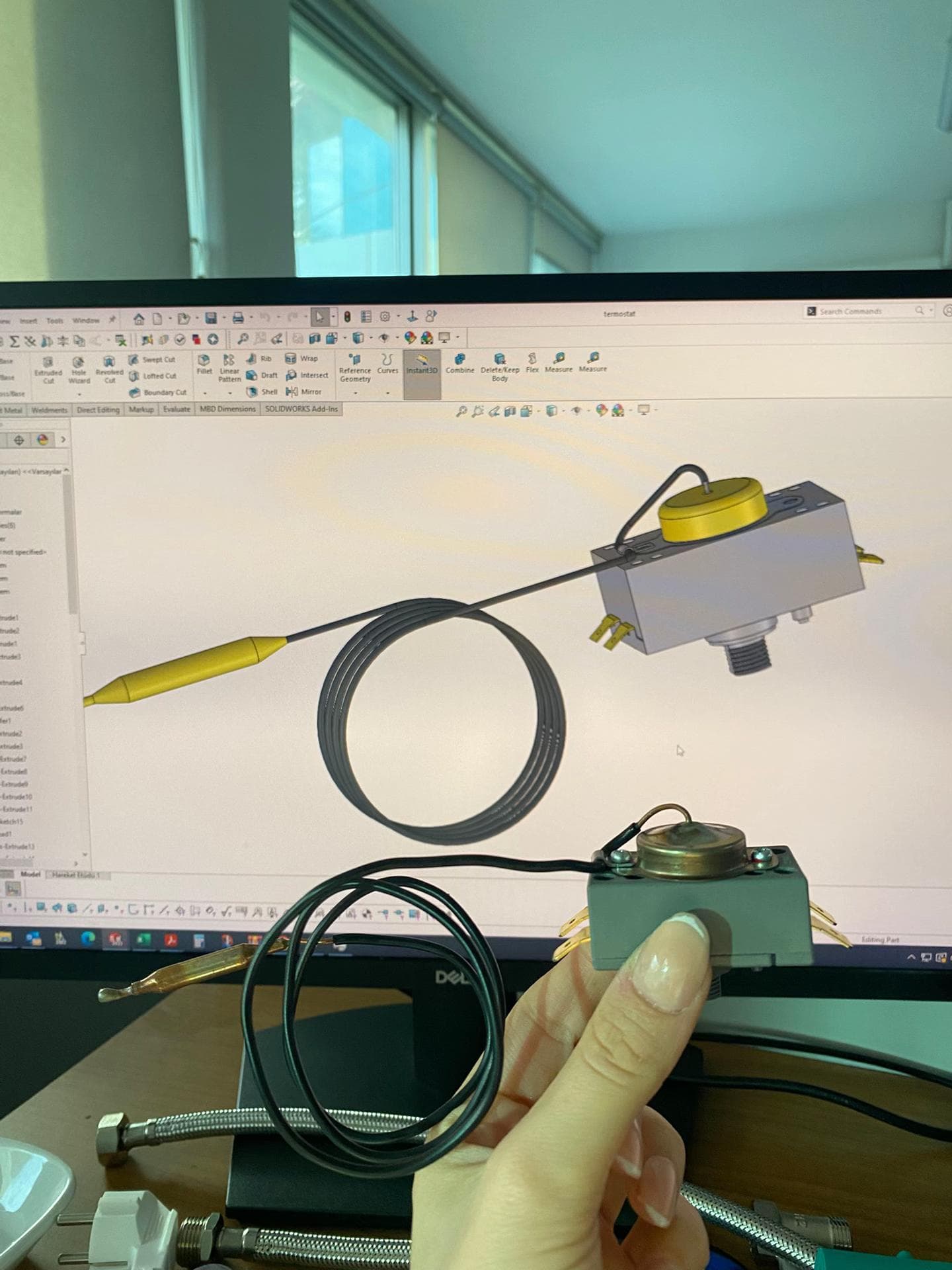

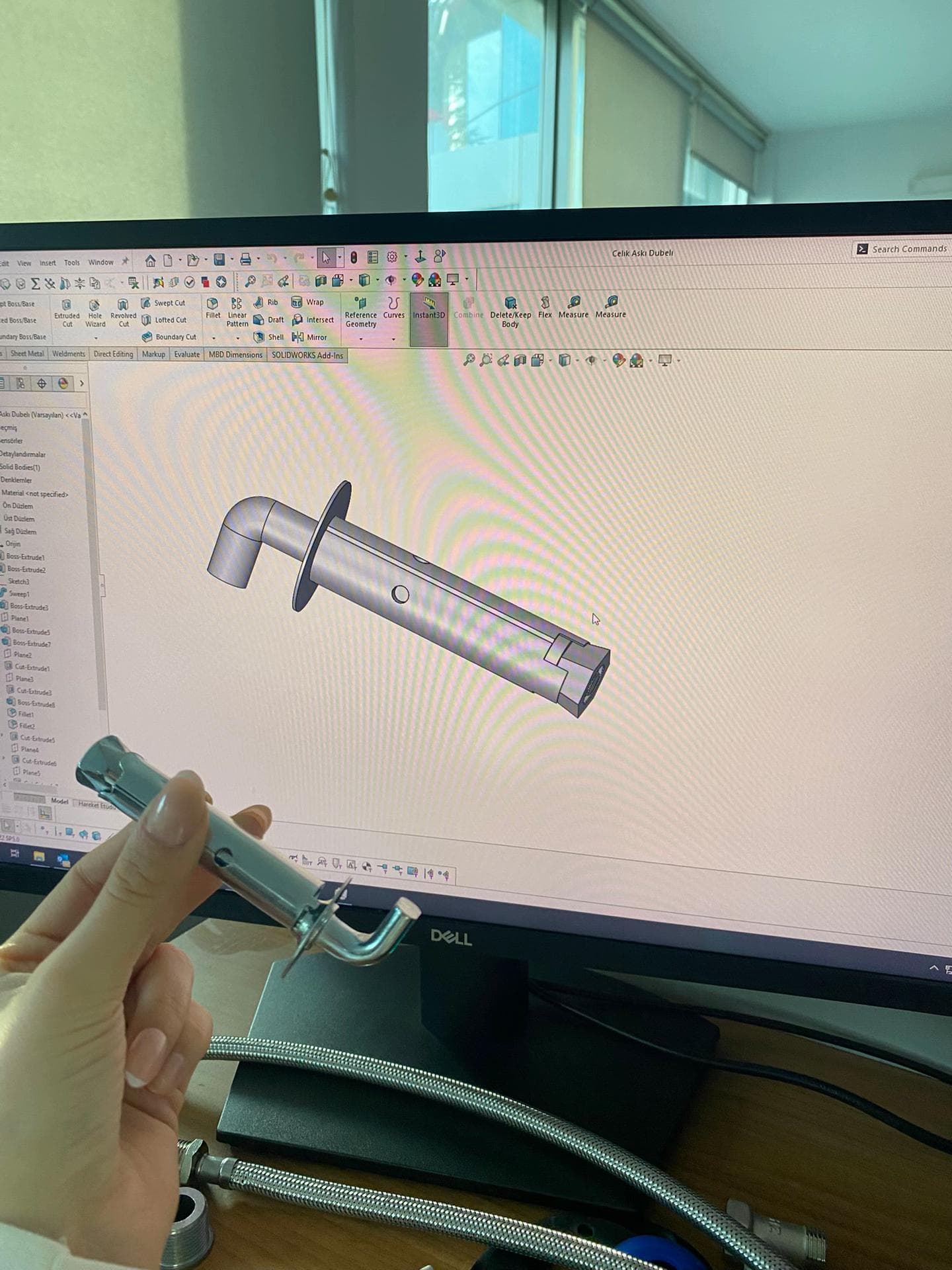

Designing a physical product requires advanced CAD engineering knowledge. Entrepreneurs stop here because they cannot translate their vision into technical blueprints.

Turning ideas into products requires understanding them first. Transforming an idea into a real product is often a major challenge.

Traditional CAD software has a multi-year learning curve, inaccessible to most.

Manufacturers demand precise technical blueprints (mediciones, materials).

The gap between what the creator imagines and what the factory interprets without clear specifications.

Turning an IDEA into a Real product.

Allowing anyone with an idea to turn it into a tangible product, without the need for unnecessary large resources, simply by telling the AI what they want to create.

AI 3D Modeling

3D creation utilizing Hunyuan-3D.

User Experience

A workflow designed to make your vision feel increasingly real and tangible at every step.

Smart Sourcing

We suggest and connect your project with the best certified manufacturers worldwide.

Idea Gallery

Chicken Shredder

Functional prototype generated from text.

Compression Cubes

Optimized organization for travel luggage.

Thermo

Ergonomic design for hot beverages.

Hierarchical Reconstruction Models for Industrial CAD

We do not use traditional LLMs because industrial CAD design does not allow for uncertainty or 'hallucinations': it requires geometric precision and deterministic mathematics. That's why we are developing a Hierarchical Reconstruction Model (HRM), an architecture designed specifically to transform implicit AI geometry (meshes, voxels, SDFs) into parametric, editable CAD ready for manufacturing. The HRM operates through hierarchical levels: first identifying fundamental geometric primitives, then topological relationships and constraints, and finally reconstructing explicit parameters (radii, tolerances, symmetries, assemblies). This approach eliminates probabilistic ambiguity and enables reliable conversion from generative models into real engineering. This layer is the critical bridge between generative AI and industrial manufacturing, currently non-existent in the market. Furthermore, the mathematical core of the HRM —based on recurrent, local, and structured operations— is exceptionally compatible with photonic accelerators, unlike dense LLMs. This enables nearly instantaneous geometric reconstruction with minimal energy consumption, positioning the system for the next generation of hardware.

Nano Banana Pro

Image Generation

Hunyuan-3D

3D Reconstruction

HRM (Industrial CAD)

Parametric B-Rep

Global Market & Scalability.

We leverage the massive growth of manufacturing.

A massive opportunity

Everything around you was manufactured by someone. The market is huge because the world is physical. We simplify that massive process starting with the hardest part: your first piece.

$12T TAM

Everything manufactured in the world

$12B SOM

Your idea made real (Where we start)

Pricing Strategy

Hobby

To validate the platform risk-free.

Starter Architect

For serious creators and startups.

Enterprise

API Access and Dedicated Support.

Roadmap 2026

We build the digital infrastructure, not the factories. Our focus is AI and network orchestration.

The Brain (AI v1.0)

Launch of the Text-to-CAD generator. Validation with 50 'Creators' designing complex products with zero engineering skills.

Network Link (API)

Digital integration with 20 existing Tier-1 factories via Alibaba API. We don't buy machines; we plug into their idle capacity intelligently.

Algorithmic Sourcing

The system automatically assigns each order to the optimal factory based on price, speed, and specialty. 'The Uber of Manufacturing'.

Decentralized Logistics

Integration with logistics partners (DHL/FedEx). Product travels directly from factory to end customer. We move the data.

The team behind

The Creation

A multidisciplinary team passionate about technology, design, and manufacturing, working to democratize physical product creation.

Yohana Berton

"Strategist in team and event organization. Expert in personnel management, capable of leading groups of over 20 people simultaneously. Solid experience in opening franchises and social media management."

Track Record

Genesis Online Academy

Created a global educational platform that has empowered hundreds of entrepreneurs, democratizing access to business strategy and advanced technology.

Ruben Palavecino

"Full Stack Developer specialized in scalable architectures. Creator of Genesis Imports automation systems and AI integration expert."

Track Record

Genesis Logistics Platform

Developed from scratch the operating system (Next.js + Firebase) that automates stock, sales, and the international supply chain between China and LATAM.

Join the Creation.

We are looking for strategic partners and investors to accelerate our technological infrastructure and expand our logistics network.

Headquarters

Menlo Park, California. CA 3639 St 143

Official Website

www.thecreation.tech